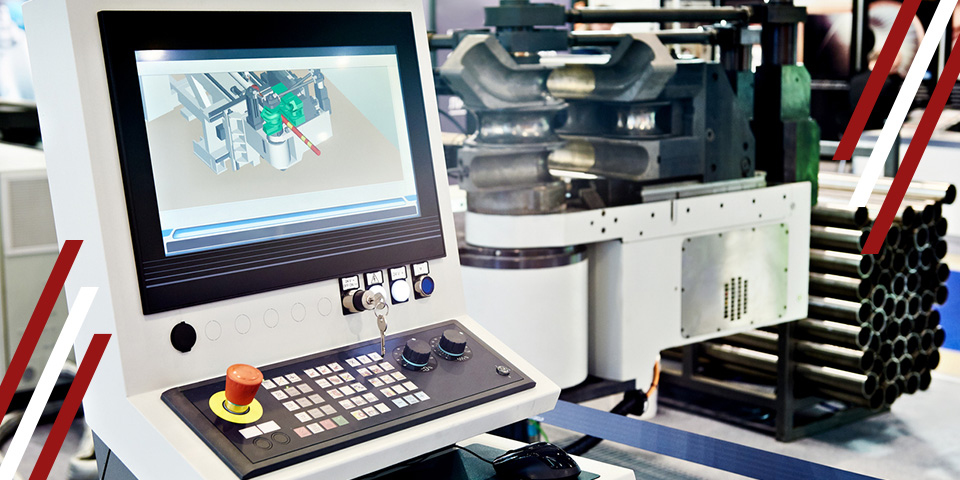

Computer numerical control machining is a revolutionary technology that has maximized efficiency, boosted productivity and enhanced product quality in the manufacturing industry. Computer-aided manufacturing software is a crucial element of CNC machines, allowing precise control and accurate results.

CAM software automates manufacturing after computer-aided design software renders 2D and 3D designs. It provides the CNC machine with precise dimensions, including tool speed and direction, to optimize the product development process. This guide explains how to improve CNC machining with CAM.

Learn About Our CNC Machining Services

CAM software converts geometrical values produced using CAD software to geometric code, a programming language that tells the CNC machine what path and speeds to follow.

The goal of using CAM software is to reduce manufacturing times, increase throughput and minimize the margins of human error during manufacturing. CAM software produces high-quality, consistent and repeatable products and parts by providing CNC machines with accurate instructions on how and where to move.

At the beginning of industrialization, manufacturing was a linear process characterized by numerous roadblocks, defects and iterations. The invention of CAD, CAM and CNC technologies created a more streamlined, efficient and collaborative manufacturing process. These technologies eliminate siloes and roadblocks between the design and manufacturing processes.

CAM software has humble beginnings dating to the late 1940s, when it was only accessible to large companies in industries such as automotive and aerospace. Back then, the software used code punched on paper to interpret product dimensions for CNC machines. The software became more affordable and accessible to manufacturers in other sectors toward the late 1960s, when developers transferred it from UNIX to PC platforms.

Today, even small family-owned businesses can enjoy CAM software’s benefits, including time and cost savings, to reap a significant return on investment.

Learn About Our CNC Machining Services

CAM software interprets the code supplied by CAD software into a language the CNC tools can read and follow. Instructions converted by CAM software include tool path and speed, machine speed, axis order and other critical parameters. By interpreting these, CNC machines can follow specific paths and run at speeds that produce parts efficiently with minimum waste.

With CAM software, you can also identify geometrical errors, streamline workflows and produce higher-quality products. The software saves time by automating repetitive tasks and allowing the virtual adjustment of designs without prototyping. It depends on three primary components to work:

Generally, CAM software automates the following manufacturing processes:

Choosing CAM software involves finding the appropriate fit for your specific applications based on your products’ specifications, tolerances and quality standards. Here are some features to consider when buying the best CAM software for CNC.

Learn About Our CNC Machining Services

Your CAM software must be compatible with the CAD software and CNC machine you use, presenting data in the same format as the other technologies or automatically converting it into acceptable formats. Compatibility ensures the software can exchange data without losing information when transferring your designs from CAD and CAM.

The best CAM software has the features and capabilities your CNC machine requires. It should also incorporate a user-friendly interface and provide comprehensive support through manuals, tutorials and customer service. You can use free demos and trials to test the functionality and usability of different CAM software before committing to one. Ensure it seamlessly integrates with other systems, such as CAD software.

Your growing business needs CAM software that is versatile enough to adapt to your changing needs. It should handle increasing production demands without compromising performance or functionality. Look for future-proof features that make your software compatible with emerging technologies.

The software provider’s reputation matters when choosing CAM software. They should be willing and able to proactively prevent and troubleshoot potential issues. Training and consultancy services are also offerings to look for to maximize your ROI. You can confirm the developer’s reputation by looking for online reviews and case studies from other users.

You want software to fit within your budget and still provide a significant ROI. Most CAM software offers pricing flexibility and numerous payment options, such as free trials, pay-per-use, perpetual and subscription models. Consider more than the purchase price by determining other ownership costs, like training, maintenance and updates.

Learn About Our CNC Machining Services

CNC machining uses CAM software to complete various tasks. It automates and optimizes the manufacturing process for benefits like these.

American Micro Industries is an industry-leading parts and components manufacturer for the automotive, aerospace, defense and other industries. We’re experts at CNC machining parts using high-quality materials to drawing specifications. We use the best CAD/CAM software to produce custom-machined components from various materials.

Call our office today or complete our convenient online form to request more information about our custom CNC machining services.