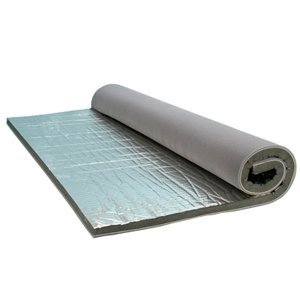

A four-layer soundproofing composite, Quiet Barrier™ Specialty Composite is used in the marine, automotive, construction, and heavy machinery industries.

Quiet Barrier™ Specialty Composite is engineered for applications that require heat resistance and noise reduction. The material has a complex, four-layer construction that makes it a premium choice for acoustic soundproofing:

American Micro Industries can fabricate Quiet Barrier Specialty Composite through die cutting. Marine-grade foam die cutting allows us to create precise cuts and clean edges. Using laser cutting, we can focus a laser beam over a substrate, producing parts quickly and effectively. When you need a company to machine marine foam and specialty composite materials efficiently and accurately, turn to us.

|

|

Quiet Barrier™ Specialty Composite has several applications, notably in the marine industry. It’s a valuable material for use on boats because of its ability to block engine noise. Many boat engines can reach 110 decibels, creating an uncomfortable and even hazardous environment for work, residence, or recreation.

The material also has applications in the automotive industry. It can help to deaden sound to create a quieter, more comfortable ride.

Since 1995, American Micro Industries has become the go-to manufacturer of materials and components for companies in the marine, automotive and aerospace industries. We can meet your company’s machine foam machining needs from our headquarters in Chambersburg, Pennsylvania.

We put customer satisfaction front and center and strive to deliver a product that goes beyond expectations. Whether you want to soundproof a recreational marine vehicle or need quality soundproofing solutions for a larger vessel, we provide fast turnaround and delivery. Contact our team today to learn more about machining and die cutting services for Quiet Barrier™ Specialty Composite.