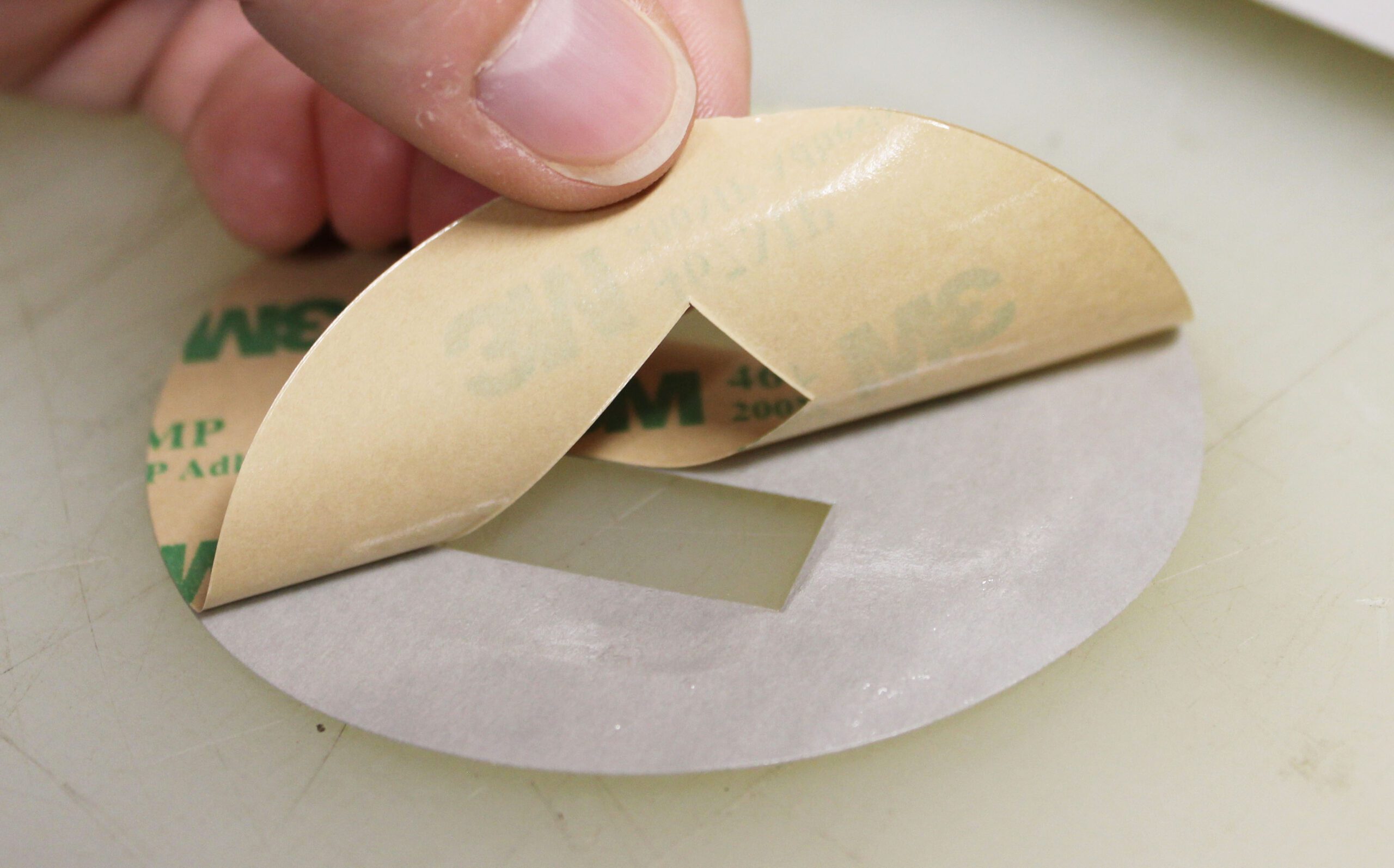

Pressure-sensitive adhesives (PSA) offer a superior fastening alternative to screws, rivets or bolts. They form a strong bond and their peel-and-stick capabilities make them fast and easy to apply on various surfaces. The application of pressure triggers the adhesive process without solvents, heat or water.

At Custom Components, a division of American Micro Industries, our expert die-cutting capabilities enable us to produce high-quality pressure-sensitive adhesives for a wide range of applications. We specialize in designing and crafting custom products for various industries that improve manufacturing processes and deliver unmatched performance at affordable prices.

While there are many established techniques for working with pressure-sensitive adhesives, die-cutting offers several valuable advantages.

The process can immediately remove the waste matrix from the outbound die-cut area. This capability prevents the machine from slowing down during high-run production processes and allows workers to avoid removing waste manually.

Die-cutting increases throughput and reduces setup times. We’re able to perform high-speed processing tasks faster and more efficiently. The result is fewer cavities that could impact quality and result in costly, time-consuming do-overs. Your business will benefit from lower project costs and fewer errors that lead to expensive do-overs.

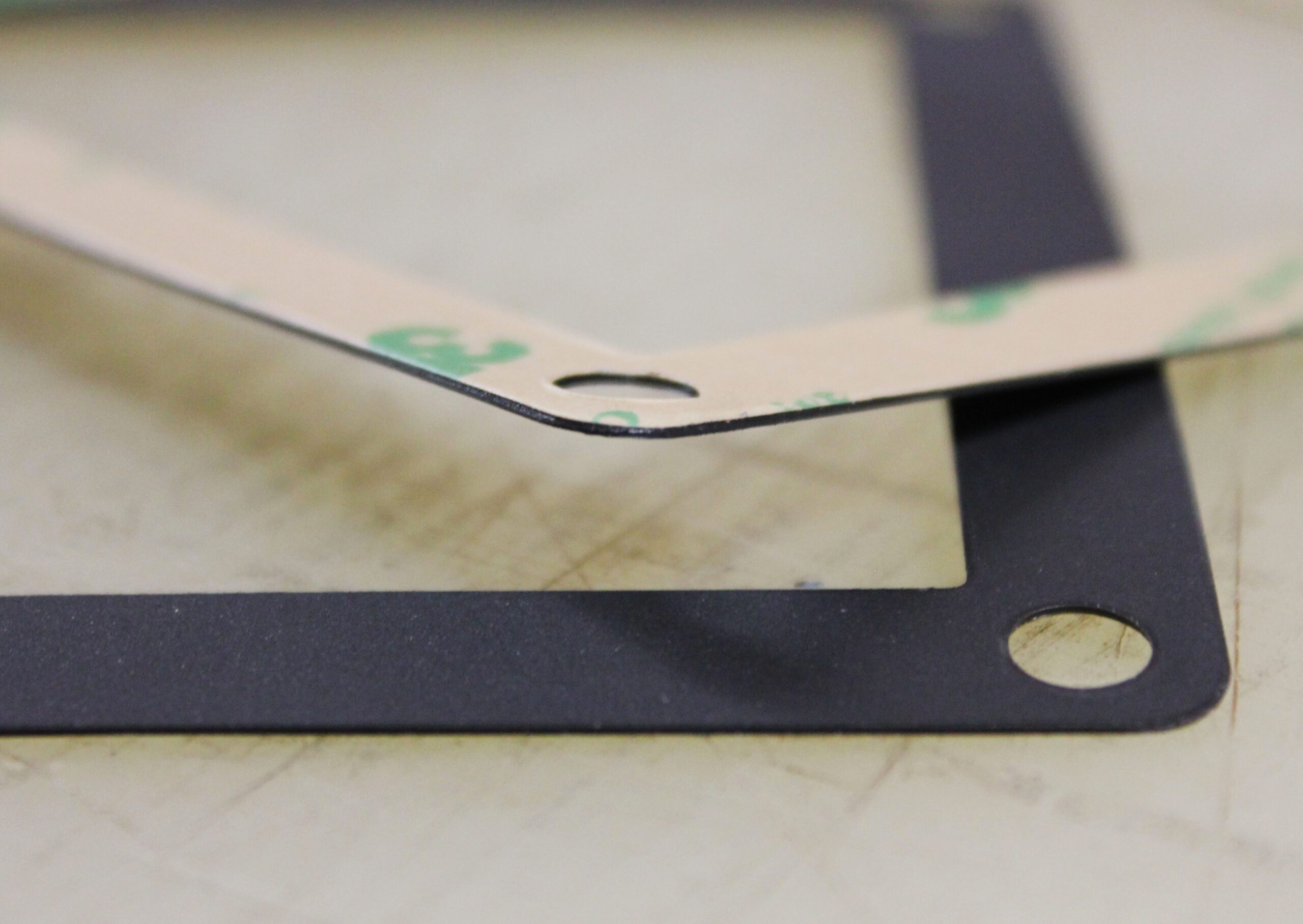

Die-cutting is ideal for PSA projects requiring adherence to strict tolerances. We can achieve a cut-to-print accuracy as tight as ± 0.015 inches, ensuring results that meet your specifications and quality expectations.

PSA die-cutting enables more accurate control of the cutting depth and minimizes cut-through of the liner. Besides increasing precision, this advantage also significantly increases the steel rule die life. Steel rule die-cutting is a cost-effective process when cutting shapes from various adhesive-coated materials.

Die-cutting adhesives with a programmable in-line sheeting knife prevent the need to sheet finished roll stock and perform other additional steps. We can complete projects faster and more efficiently while optimizing turnaround times for our customers.

For PSA die-cutting projects involving the lamination of sheet stock, we can transform it into a continuous loop when feeding the material into the machinery. The result is a faster processing speed and the ability to complete laminating jobs more quickly.

We utilize advanced laminating equipment that can combine multiple layers of pressure-sensitive adhesives. This process is applicable when working with various material types.

PSA die-cutting is compatible with customized techniques, enabling us to deliver tailored results that meet your unique project requirements.

The Custom Components division of American Micro Industries has been offering premium die-cutting services since 1995. We focus on delivering superior results at affordable prices, ensuring our customers can meet their quality expectations and minimize project costs.

Our vast die-cutting capabilities encompass the following processes:

We perform all our die-cutting work in-house, enabling us to monitor every aspect of the process and implement stringent quality control measures. We can deliver turnkey solutions that eliminate lag time and allow you to maintain tight production schedules. Our team includes well-trained, experienced professionals who take pride in their work and strive to deliver the best outcome for every job, regardless of the size, scope or complexity.

Our Chambersburg, PA-based die-cutting company serves businesses like yours throughout the Mid-Atlantic region and nationwide. When you partner with us, you can expect low tooling cost, lightning-fast turnaround times and no restrictive minimum order requirements. You’ll also receive excellent service to optimize your customer experience.

Take the next step by requesting a free PSA die-casting quote today. If you would like additional information about our processes or services, call us at 866-774-9353 or view our contact page to locate the employee who can address your needs.